Shakeout Machine

Shakeoutmachine

Shakeoutmachine

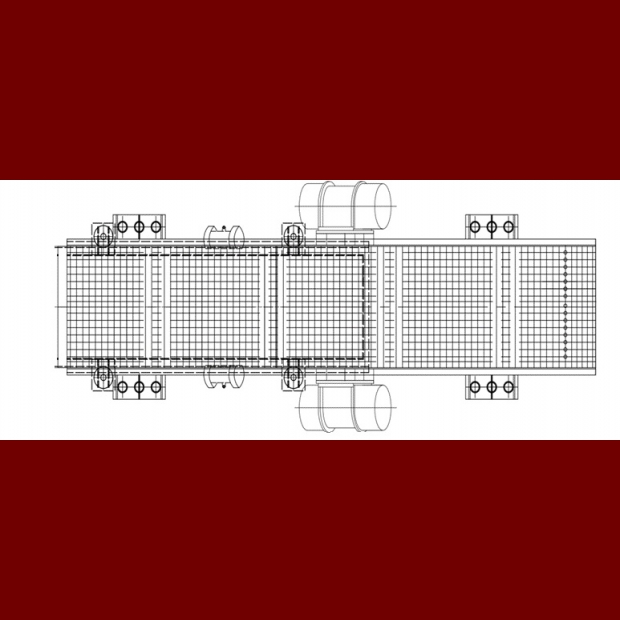

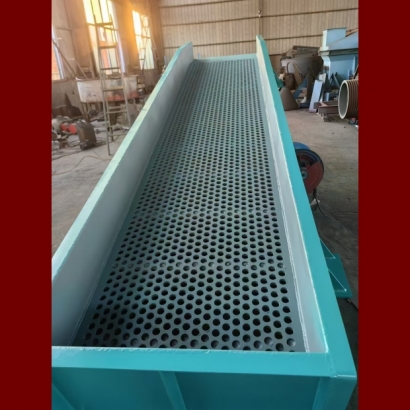

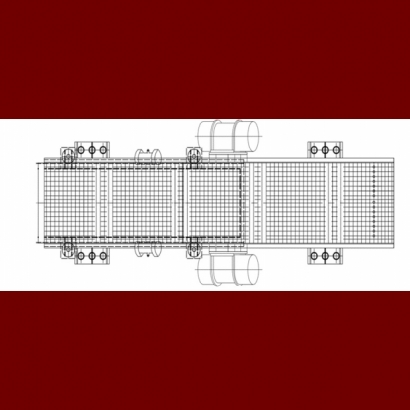

This series of shakeout machines are suitable for manual molding, mechanized and semi-automatic molding and pouring of small and medium-sized casting molds in the casting workshop, and separating the sand from the mold box and castings. The separated sand pellets are further crushed and pass through the grid holes to fall onto the vibrating conveyor or belt conveyor. According to the weight of the workpiece and the size of the sand box, two or four units can be installed in parallel.

DETAIL

A pair of symmetrically and horizontally installed excitation motors operate in reverse synchronization, the horizontal component forces are mutually balanced, and the vertical resultant force allows the frame of the shakeout machine to vibrate positively with a certain acceleration (no load), and the mold is thrown (with or without a sand box). Then the sand falls and collides with the grid to separate the sand mold from the sand box. After the sand mass breaks, it falls back onto the sand belt through the grid holes. Since the resultant force of the vibration motor is perpendicular to the upper plane of the grid, the castings and sand masses cannot be unloaded on their own and must be lifted off the machine by using a lifting equipment to achieve casting and shakeout.

Two vibration motors are installed symmetrically, with a pair of eccentric plates at both ends of each motor. The excitation force of the motor can be adjusted by changing the angle between the two eccentric plates. When the angle between the two eccentric blocks is zero, the excitation force of the vibration motor is the maximum value. When the angle between the eccentric blocks is 180 °, the excitation force of the vibration motor is the minimum value.