Green Sand System-Cooling

-

Read More

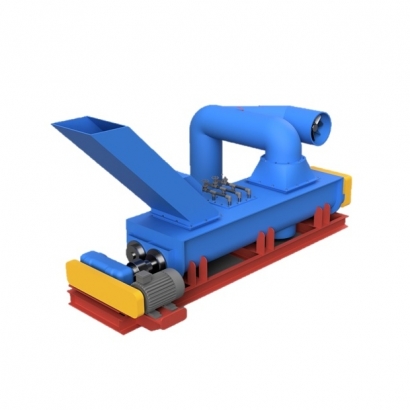

Double Shaft Humidify Mixer

Double Shaft Humidify MixerDouble Shaft Humidify Mixer

SJ Series Double Shaft Stirring Cooler is the use of two symmetrical spiral axis synchronous rotation, while conveying the material at the same time according to the different temperature of the material by adding a different amount of water mixing, so that the material to achieve the purpose of humidification and cooling.

Two sets of spiral blades are used for mixing, with high mixing efficiency and small floor space. Driven by the reducer, the spiral shaft drives stirring at a reasonable speed. The spiral blades are made of high-strength wear-resistant alloy surfacing and have a long service life. The double-shaft mixer is driven by a hard-tooth surface reducer, which ensures smooth rotation and reliable operation. The twin-shaft mixer is fed from the top and discharged from the bottom, with a reasonable structure. The joint surfaces are tightly sealed and operate smoothly. The double-shaft mixing humidifier is equipped with a nozzle, which is connected to the water-adding humidification system to ensure uniform water spraying, and can meet different needs by controlling the amount of water sprayed. -

Read More

Double Shaft Humidify Mixer Temperature and Humidity Control System

Double Shaft Humidify Mixer Temperature and Humidity Control SystemDouble Shaft Humidify Mixer Temperature and Humidity Control System

The SJAW system is a special water-adding cooling system designed specifically for dual-axis humidification mixers. It makes comprehensive judgments about adding water based on the environmental parameters of the factory, actual sand temperature conditions, humidity, etc. The metered water-adding part can add water with high accuracy. Combined with dual-axis stirring, it becomes the core control parameter center in the recycling system. -

Read More

Test-Products-titleTest-Products-title

Test-Products-titleTest-Products-titleTest-Products-titleTest-Products-title

S83 series double-disc stirring cooling machine is mainly used for cooling old sand in sand processing.

Structural features: a transmission mechanism is formed by means of driving two reducers with one motor; a working mechanism is formed by two sets of mixing devices.

During working, the hot old sand, which has been humidified (with a moisture content of about 4-5%), is fed into the machine through the feeding port and is strongly stirred by the scraper, with two-ring motions inside the plate; at the same time, cold air is blown into the machine from the air inlet on the enclosure to exchange heat with the sand, and the hot air is discharged from the outside of the machine through the top exhaust duct; under the action of the external scraper, the sand pushes the discharging door open on the side wall to discharge sand from the machine. -

Read More

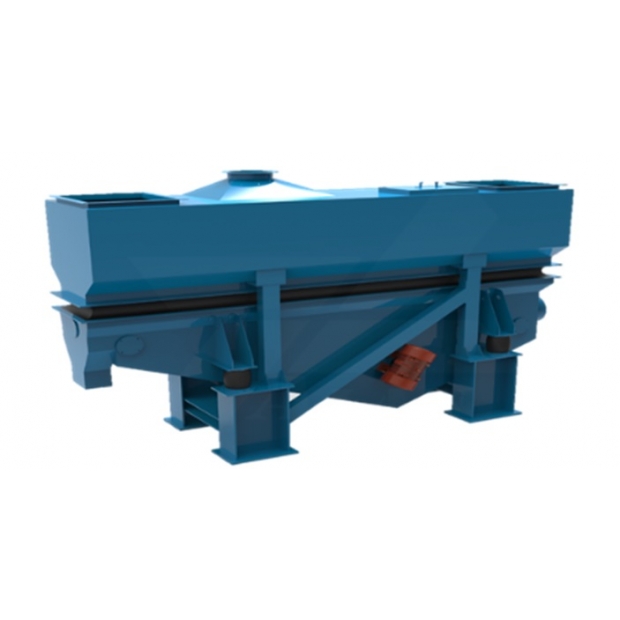

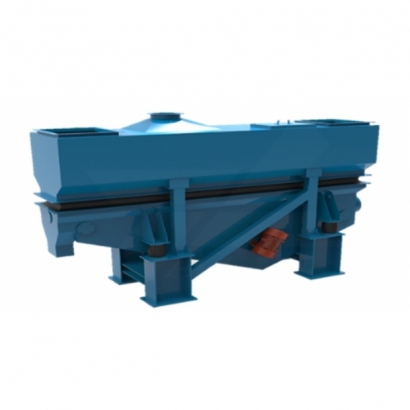

SL Type Vibrating Boiling Cooling Bed

SL Type Vibrating Boiling Cooling BedSL Type Vibrating Boiling Cooling Bed

SL applies to the cooling of sodium silicate sand resin sand and clay sand.