All Product

-

Read More

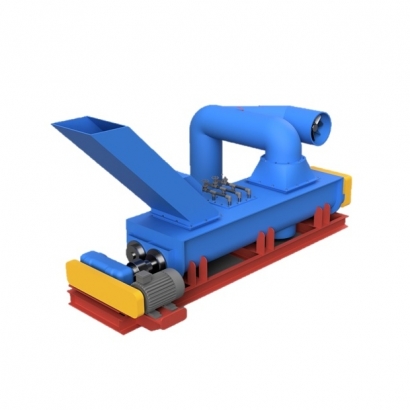

Belt-type permanent-magnetic separator

Belt-type permanent-magnetic separatorBelt-type permanent-magnetic separator

The permanent-magnetic separator produced by our factory is widely used in industries such as metallurgy, mining, power generation, combustion, building materials, ceramics, flour, casting, etc. It can be used to separate strong magnetic substances mixed in loose materials including iron nails, iron beans, cold iron, core bones, and sprues from the materials to protect process equipment and transportation equipment for crushing, screening, lifting, feeding, mixing, and shaping. It can also be used to recycle scrap iron and be used for magnetic raw materials such as powder metallurgy and selected iron oxide scales. -

Read More

S Type Fine Hexagonal Screen Mechanical

S Type Fine Hexagonal Screen MechanicalS Type Fine Hexagonal Screen Mechanical

S Type Fine Hexagonal Screen Mechanical is used for fine screening of old sand in the sand processing department of the casting workshop. During working, the old sand enters the screen through the feeding port. The spiral blades in the feeding section and the rotation of the screen allow the materials to rise, fall, and move forward to achieve crushing and fine screening. At the same time, under the action of the ventilation and dust removal system, the old sand has a certain cooling effect, and the screened residue is discharged from the waste port. -

Read More

Shakeoutmachine

ShakeoutmachineShakeoutmachine

This series of shakeout machines are suitable for manual molding, mechanized and semi-automatic molding and pouring of small and medium-sized casting molds in the casting workshop, and separating the sand from the mold box and castings. The separated sand pellets are further crushed and pass through the grid holes to fall onto the vibrating conveyor or belt conveyor. According to the weight of the workpiece and the size of the sand box, two or four units can be installed in parallel. -

Read More

MOR Composite Sand and Casting Screening and Grinding Drum

MOR Composite Sand and Casting Screening and Grinding DrumMOR Composite Sand and Casting Screening and Grinding Drum

This machine is mainly used for shakeout cleaning of batch production of cast iron, cast copper, and cast aluminum parts, as well as for slow cooling of the workpieces. It is equipped with a dust removal sheet with a recommended dust removal capacity of 10000~12000m3/h. It can improve the cooling effect, capture the ash powder content in the low old sand, increase the wet compressive strength and air permeability of the molding sand, and thus improve the casting yield. Its overall performance is relatively good. The size of the cleaned workpiece should be less than 1/4~1/5 of the diameter of the inner drum.

The workpiece and sand entering the inner drum can quickly sieve the scattered sand at the inlet end. During the turnover of the casting, it not only rubs off the adhered particles, but also crushes and screens the unbroken particles. There is always a small amount of sand retained in the inner drum as a cushion layer for the workpiece, which solves the problem of collision and damage to thin-walled parts. On the entire length of the inner drum, the screened sand that enters between the inner and outer drums are guided by spiral blades and returns to the inlet end for discharging. -

Read More

Double Shaft Humidify Mixer

Double Shaft Humidify MixerDouble Shaft Humidify Mixer

SJ Series Double Shaft Stirring Cooler is the use of two symmetrical spiral axis synchronous rotation, while conveying the material at the same time according to the different temperature of the material by adding a different amount of water mixing, so that the material to achieve the purpose of humidification and cooling.

Two sets of spiral blades are used for mixing, with high mixing efficiency and small floor space. Driven by the reducer, the spiral shaft drives stirring at a reasonable speed. The spiral blades are made of high-strength wear-resistant alloy surfacing and have a long service life. The double-shaft mixer is driven by a hard-tooth surface reducer, which ensures smooth rotation and reliable operation. The twin-shaft mixer is fed from the top and discharged from the bottom, with a reasonable structure. The joint surfaces are tightly sealed and operate smoothly. The double-shaft mixing humidifier is equipped with a nozzle, which is connected to the water-adding humidification system to ensure uniform water spraying, and can meet different needs by controlling the amount of water sprayed. -

Read More

Double Shaft Humidify Mixer Temperature and Humidity Control System

Double Shaft Humidify Mixer Temperature and Humidity Control SystemDouble Shaft Humidify Mixer Temperature and Humidity Control System

The SJAW system is a special water-adding cooling system designed specifically for dual-axis humidification mixers. It makes comprehensive judgments about adding water based on the environmental parameters of the factory, actual sand temperature conditions, humidity, etc. The metered water-adding part can add water with high accuracy. Combined with dual-axis stirring, it becomes the core control parameter center in the recycling system. -

Read More

Test-Products-titleTest-Products-title

Test-Products-titleTest-Products-titleTest-Products-titleTest-Products-title

S83 series double-disc stirring cooling machine is mainly used for cooling old sand in sand processing.

Structural features: a transmission mechanism is formed by means of driving two reducers with one motor; a working mechanism is formed by two sets of mixing devices.

During working, the hot old sand, which has been humidified (with a moisture content of about 4-5%), is fed into the machine through the feeding port and is strongly stirred by the scraper, with two-ring motions inside the plate; at the same time, cold air is blown into the machine from the air inlet on the enclosure to exchange heat with the sand, and the hot air is discharged from the outside of the machine through the top exhaust duct; under the action of the external scraper, the sand pushes the discharging door open on the side wall to discharge sand from the machine. -

Read More

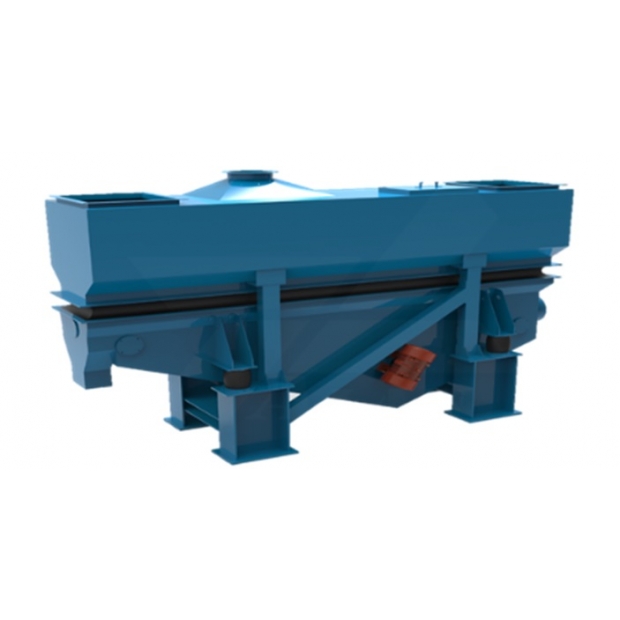

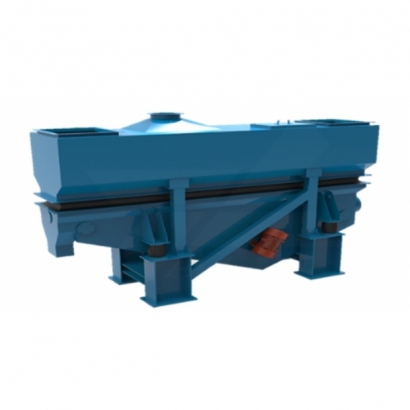

SL Type Vibrating Boiling Cooling Bed

SL Type Vibrating Boiling Cooling BedSL Type Vibrating Boiling Cooling Bed

SL applies to the cooling of sodium silicate sand resin sand and clay sand. -

Read More

GS Type High Efficiency Rotor Sand Mixer

GS Type High Efficiency Rotor Sand MixerGS Type High Efficiency Rotor Sand Mixer

It is mainly used foundry sand mixing machines can be used in a single sand shape, but also mixing dry scrub, since the hard sand, sand veil and back, can also be used for glass, ceramics, refractories, etc. Mixing of powder industry granular materials. -

Read More

Automatic sand analysis and water adding machine

Automatic sand analysis and water adding machineAutomatic sand analysis and water adding machine

Water is filled to this machine by means of calculating and controlling the amount of water added with a certain logical function relationship based on the difference between the value of the compactability and the target value, so that the compactability may be controlled within the set target range. The water-filling system is designed with two water pipes for water filling and water replenishment separately, a flow sensor is used for quantification, and a solenoid valve is used to control the stop and start of water filling.