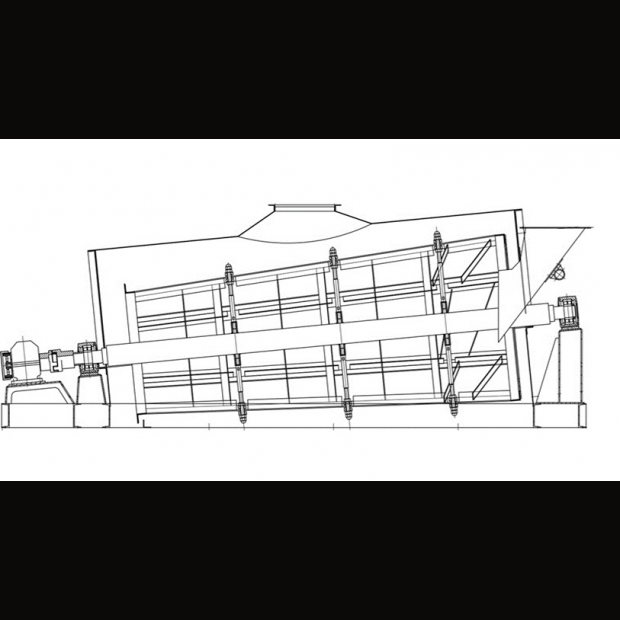

Fine Hexagonal Screen Mechanical

S Type Fine Hexagonal Screen Mechanical

S Type Fine Hexagonal Screen Mechanical

S Type Fine Hexagonal Screen Mechanical is used for fine screening of old sand in the sand processing department of the casting workshop. During working, the old sand enters the screen through the feeding port. The spiral blades in the feeding section and the rotation of the screen allow the materials to rise, fall, and move forward to achieve crushing and fine screening. At the same time, under the action of the ventilation and dust removal system, the old sand has a certain cooling effect, and the screened residue is discharged from the waste port.

DETAIL

On the basis of the old hexagonal screen (small-end feeding and large-end discharging), this machine adopts advanced experience from both domestic and foreign sources, and fully utilizes the free falling law of objects. The form of large-end side feeding and small-end discharging with a spindle inclination of 5.5 °~6 ° is adopted to avoid materials jamming of the spindle and sleeve during materials flow. Moreover, spiral blades with a lifting angle of 20 ° are configured in the feeding section for more smooth flow of materials.

The material moves forward a certain distance every time it rises, which avoids the phenomenon that the advancing of materials in traditional hexagonal screen are fully completed by tilting of the screen cylinder surface or the spiral blades.

Cold-drawn stainless steel high-strength coarse steel wire woven mesh with 8×18 or 6×16 long hole mesh are used, which has a service life of more than three years, and is especially suitable for wet, hot, and sticky materials. The outer six corners of the screen are fixed tightly to each other, with a tight mesh surface that is not easily broken and has a good rebound effect for easy replacement.

Large-end feeding increases the screen area by 30-40%. The screen adopts rectangular mesh to increase the chance of materials passing through the screen. Each side of the hexagonal screen protrudes outward, which further increases the screen area and improves the screening efficiency.

The screen speed (approximately theoretical speed) is increased, and the height of material rise and the impact force of material falling are improved, which is beneficial for crushing and screening, and the efficiency is improved.

It is featured with air inlet, strong ventilation, mud content control, and a certain cooling effect is achieved