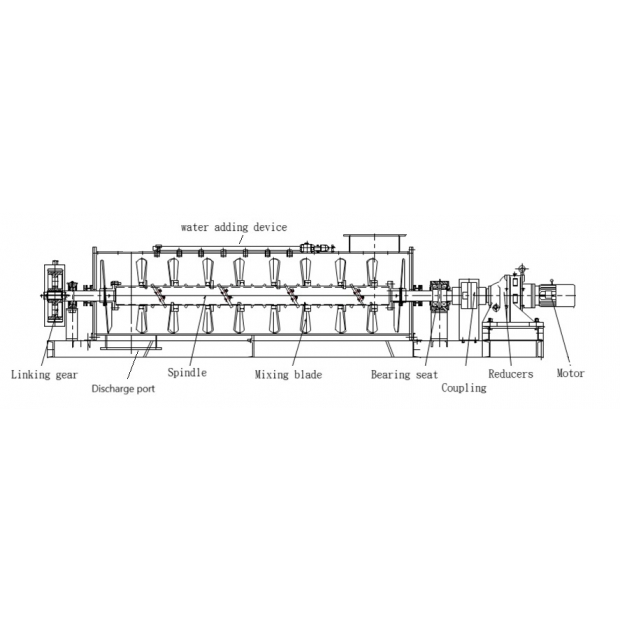

Double Shaft Humidify Mixer

Double Shaft Humidify Mixer

Double Shaft Humidify Mixer

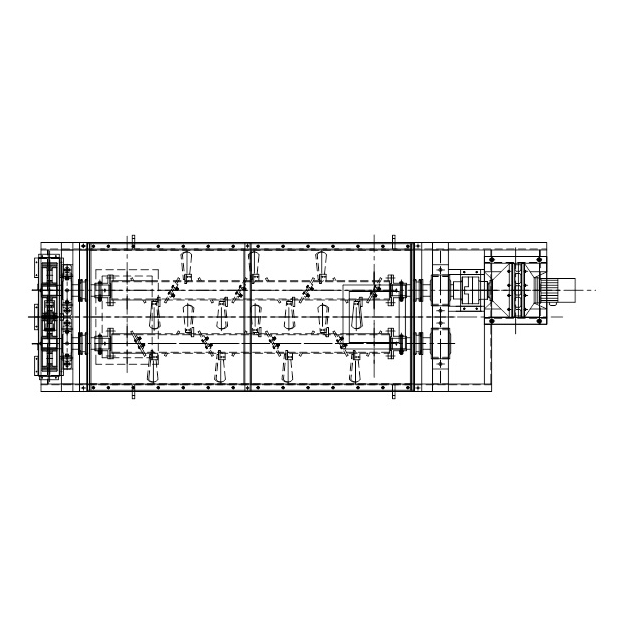

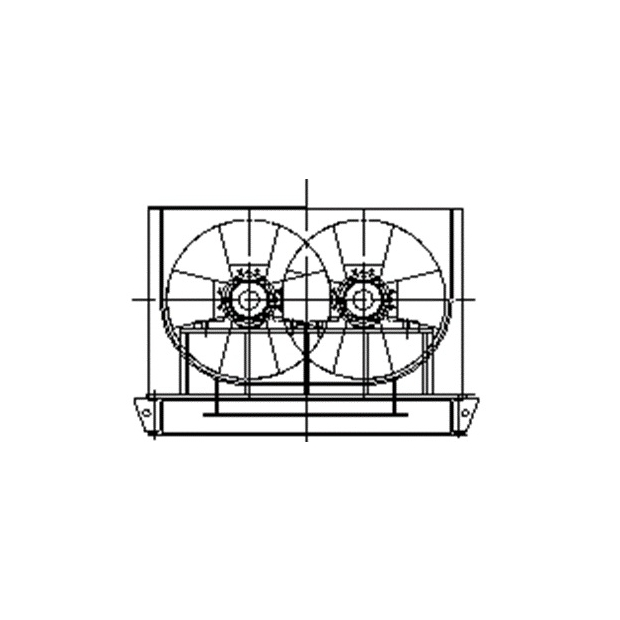

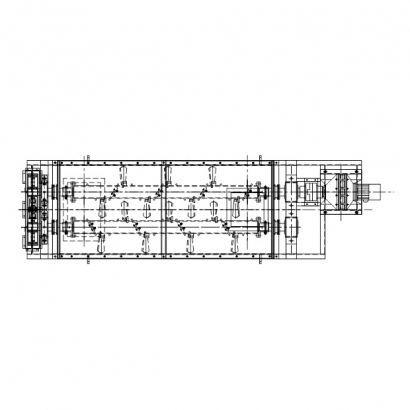

SJ Series Double Shaft Stirring Cooler is the use of two symmetrical spiral axis synchronous rotation, while conveying the material at the same time according to the different temperature of the material by adding a different amount of water mixing, so that the material to achieve the purpose of humidification and cooling.

Two sets of spiral blades are used for mixing, with high mixing efficiency and small floor space. Driven by the reducer, the spiral shaft drives stirring at a reasonable speed. The spiral blades are made of high-strength wear-resistant alloy surfacing and have a long service life. The double-shaft mixer is driven by a hard-tooth surface reducer, which ensures smooth rotation and reliable operation. The twin-shaft mixer is fed from the top and discharged from the bottom, with a reasonable structure. The joint surfaces are tightly sealed and operate smoothly. The double-shaft mixing humidifier is equipped with a nozzle, which is connected to the water-adding humidification system to ensure uniform water spraying, and can meet different needs by controlling the amount of water sprayed.

Two sets of spiral blades are used for mixing, with high mixing efficiency and small floor space. Driven by the reducer, the spiral shaft drives stirring at a reasonable speed. The spiral blades are made of high-strength wear-resistant alloy surfacing and have a long service life. The double-shaft mixer is driven by a hard-tooth surface reducer, which ensures smooth rotation and reliable operation. The twin-shaft mixer is fed from the top and discharged from the bottom, with a reasonable structure. The joint surfaces are tightly sealed and operate smoothly. The double-shaft mixing humidifier is equipped with a nozzle, which is connected to the water-adding humidification system to ensure uniform water spraying, and can meet different needs by controlling the amount of water sprayed.

DETAIL

2. Reasonable spray device to achieve good mixing effect with gray water.

3. The mixer blades made of high wear-resistant materials provide long service life and reliable guarantee of normal operation.

4. Reasonable design of the shaft seat and sealing device structure makes maintenance easy and completely eliminates water leakage and leakage.

5. Add pre-water section to make the mixing effect better.

6. The spacious flip-up access door makes maintenance work comfortable and easy.

7. Flexible and reliable electrical control system makes operation safe and easy.

8. At the same time, it has the functions of adding water, stirring, dust removal and sand breaking block. It is a trinity. It is especially suitable for

production lines with densely arranged line positions.

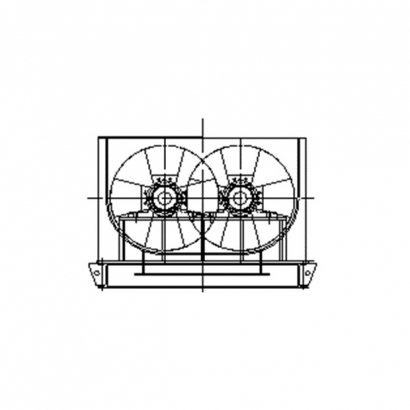

9. The active exhaust system can effectively prevent the dust removal equipment from being clogged due to the accumulation of dusty water vapor, and ㄏ

enhance the internal heat dissipation effect of the two shafts.